Air Compressor for Pharmaceutical Manufacturing

PRS Compressors provides ultra-clean, oil-free air solutions designed specifically for pharmaceutical manufacturing environments. In this highly regulated industry, compressed air must meet strict quality standards, especially for applications involving direct or indirect contact with products. Our oil-free screw and scroll compressors deliver Class 0 certified air, ensuring zero contamination and complete compliance with GMP, ISO, and FDA guidelines.

Compressed air is essential in pharmaceutical operations such as tablet coating, capsule filling, fermentation, air conveying, packaging, and cleanroom environments.

Oil-free compressors provide contamination-free air, safeguarding medicine quality and meeting strict regulatory standards.

These are the Compressors Used in Pharmaceutical Field

A concise overview of the key compressor types that power critical healthcare systems.

Oil-Free Scroll Air Compressor

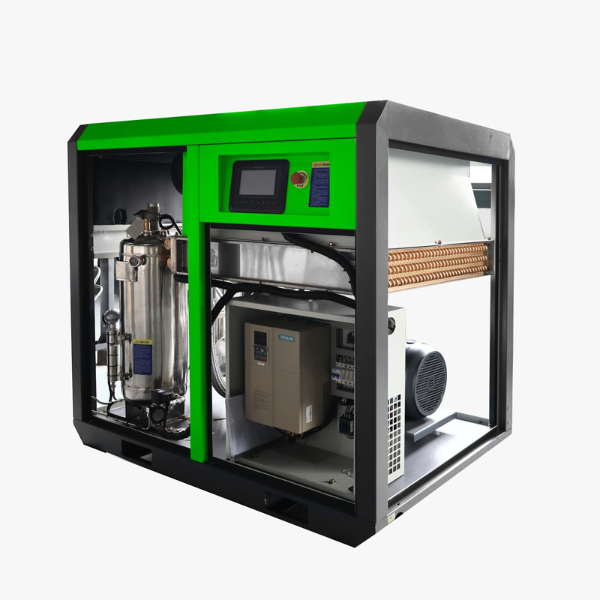

Oil-Free Screw Air Compressor

Oil-Lubricated Piston Compressor

Portable Oil-Free Compressors

Why is oil-free compressed air important in pharmaceutical manufacturing?

Which type of air compressor is best for cleanroom and sterile areas?

Can PRS compressors meet regulatory standards for pharmaceutical plants?

How often should a pharmaceutical air compressor be maintained?

Ready for Personalized Support?

Get expert help tailored to your exact needs—whenever you need it.