Air Compressor for Ceramic

The ceramic manufacturing process depends heavily on reliable, high-pressure compressed air to maintain quality, speed, and consistency throughout production. PRS Compressors offers durable and energy-efficient oil-lubricated and oil-free air compressors that meet the demanding needs of tile pressing, glazing, polishing, and kiln automation.

Compressed air is used in every stage—from spray drying and slip pumping to pneumatic conveyance and packaging. PRS screw and piston compressors are built for continuous-duty operation, delivering clean and stable air even in high-temperature, dusty environments common in ceramic plants.

These are the Compressors Used in Ceramic Industry

A concise overview of the key compressor types that power critical systems.

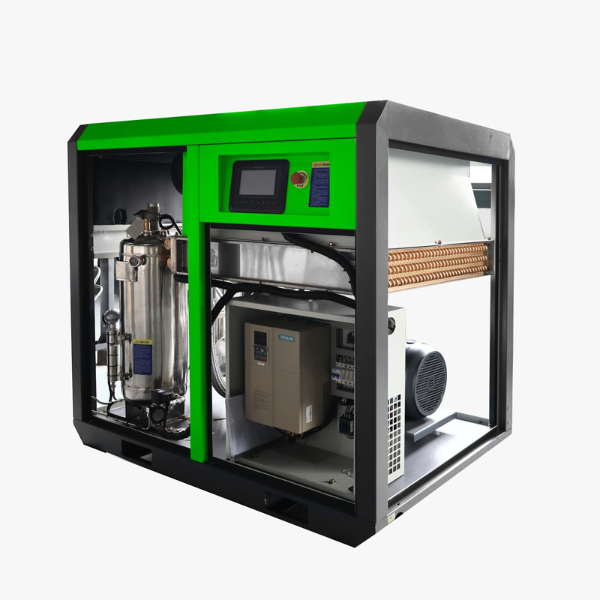

Oil-Lubricated Screw Air Compressor

Oil-Free Screw Air Compressor

Piston (Reciprocating) Air Compressor

High-Pressure Booster Compressor

What type of air compressor is best for ceramic tile manufacturing?

Is oil-free air necessary for ceramic processes?

Can piston compressors be used in ceramic factories?

Why are booster compressors used in ceramics?

Ready for Personalized Support?

Get expert help tailored to your exact needs—whenever you need it.