Air Compressor for CNC Machining

CNC machining demands precision, speed, and clean operation—and compressed air is a vital part of that process. PRS Compressors provides high-performance screw and oil-free air compressors that deliver consistent airflow for tool changes, chip removal, coolant spray, pneumatic control systems, and part cleaning.

Our compressors are built to handle continuous-duty cycles, ensuring your CNC machines operate with maximum efficiency and minimal downtime. With options for air dryers, filters, and silent operation, PRS compressors offer the clean, dry, and reliable compressed air needed for tight tolerances and smooth finishes in CNC operations.

These are the Compressors Used in CNC Machining Field

A concise overview of the key compressor types that power critical systems.

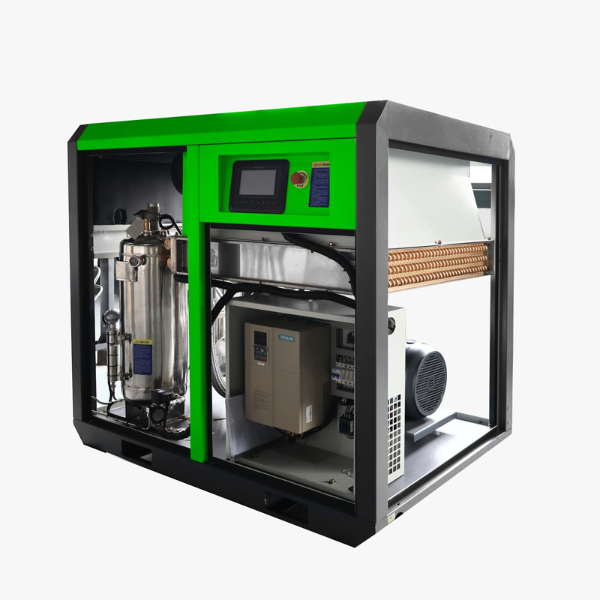

Oil-Lubricated Compressor

Oil-Free Screw Air Compressor

Tank-Mounted Reciprocating

Scroll Compressor

Why is compressed air essential in CNC machining?

Which type of air compressor is best for CNC machines?

How much pressure is required for CNC machine operations?

How do I prevent moisture from damaging my CNC machines?

Ready for Personalized Support?

Get expert help tailored to your exact needs—whenever you need it.