Air Compressor for Manufacturing

PRS Compressor offers high-performance air compressors tailored for the diverse needs of the manufacturing sector. From precision tools to automated machinery, our compressors provide consistent, high-quality compressed air essential for efficient operations. Designed for durability and energy efficiency, PRS air compressors—available in oil-lubricated, oil-free, and screw models—support a wide range of manufacturing processes such as metal fabrication, assembly lines, packaging, plastics, and more. With reliable performance, low maintenance, and superior air output, PRS compressors help manufacturers boost productivity while reducing operational costs.

These are the Compressors Used in Manufacturing Field

A concise overview of the key compressor types that power critical healthcare systems.

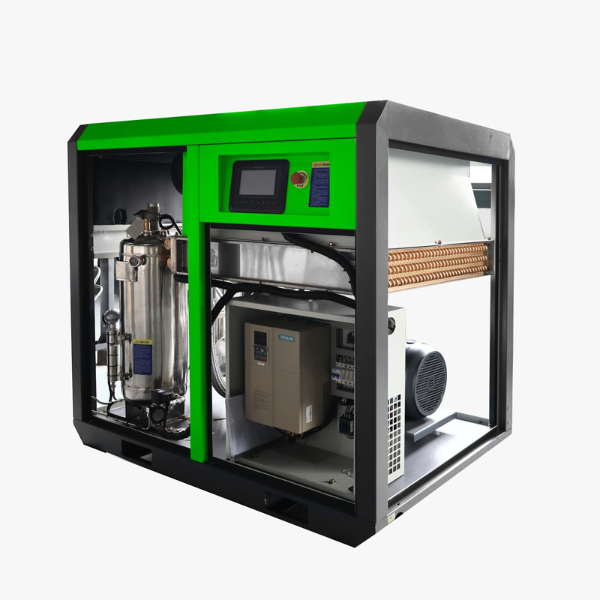

Oil-Lubricated Screw Air Compressor

Oil-Free Screw Air Compressor

Piston (Reciprocating) Air Compressor

High-Pressure Air Compressor

Which type of air compressor is best suited for manufacturing industries?

What size compressor is needed for manufacturing?

Do manufacturing compressors need regular maintenance?

What’s the benefit of using PRS screw compressors in manufacturing?

Ready for Personalized Support?

Get expert help tailored to your exact needs—whenever you need it.