Air Compressor for Pet Bottle

PRS Compressors delivers advanced high-pressure air compressor systems designed specifically for PET bottle manufacturing and blow molding applications. In the PET industry, precise and powerful compressed air is essential to shape preforms into bottles using blow molding machines. Our oil-free and oil-lubricated high-pressure compressors ensure clean, dry air up to 40 bar and beyond, providing the consistent pressure required for high-speed production lines.

Engineered for energy efficiency and reliability, PRS PET bottle air compressors are ideal for bottled water, soft drink, pharmaceutical, and edible oil manufacturers.

These are the Compressors Used in Pet Bottle Field

A concise overview of the key compressor types that power critical healthcare systems.

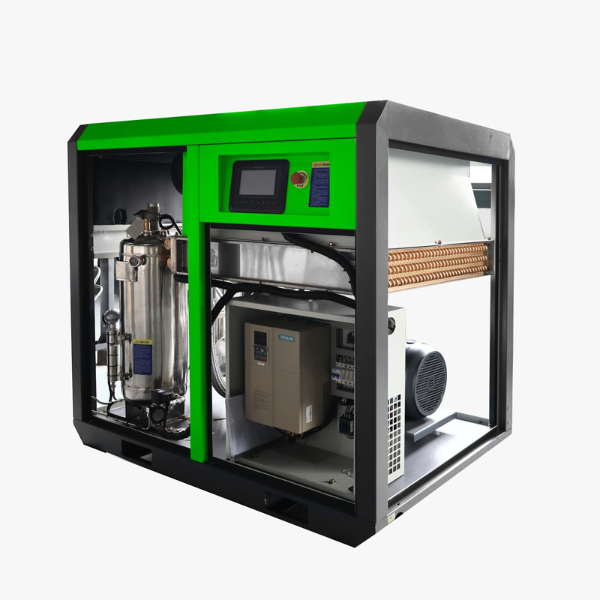

High-Pressure Oil-Free Screw Air Compressor

Oil-Lubricated High-Pressure Piston Compressor

Two-Stage Reciprocating Compressor

Booster Compressor

Which type of air compressor is best for PET bottle blowing?

What pressure range is required for PET bottle production?

Is oil-free air mandatory for PET bottle manufacturing?

Can PRS compressors handle continuous 24/7 operations in PET plants?

Ready for Personalized Support?

Get expert help tailored to your exact needs—whenever you need it.