Air Compressor for Textiles

PRS Compressors provides reliable and energy-efficient air compressor solutions tailored for the textile industry. From spinning and weaving to dyeing and finishing, compressed air plays a vital role in operating pneumatic looms, air-jet machines, auto-coners, and dyeing systems. PRS air compressors—available in both oil-lubricated and oil-free models—ensure consistent air delivery, reduce downtime, and enhance fabric quality by maintaining precision in operations.

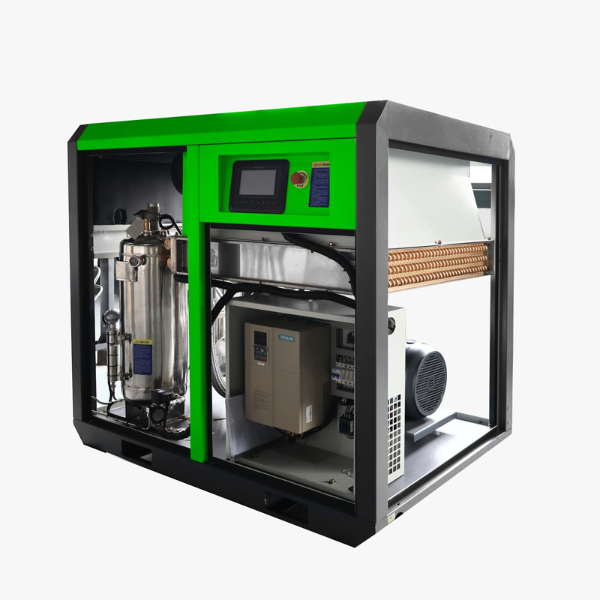

Designed for 24/7 industrial use, our screw and piston compressors meet the rigorous demands of textile units while offering lower power consumption, reduced noise, and high durability.

These are the Compressors Used in Textiles Field

A concise overview of the key compressor types that power critical healthcare systems.

Oil-Lubricated Screw Air Compressor

Oil-Free Screw Air Compressor

Piston (Reciprocating) Air Compressor

High-Pressure Air Compressor

Which type of air compressor is best suited for textile manufacturing?

Why is compressed air important in textile production?

How do I choose the right compressor size for my textile unit?

How often should textile compressors be maintained?

Ready for Personalized Support?

Get expert help tailored to your exact needs—whenever you need it.