Grow with Us

Air Compressors for Chemical

PRS Compressors provides robust and high-performance air compressor solutions specifically designed for the demanding conditions of the chemical industry. From process control and material handling to pneumatic conveying and instrument air, compressed air plays a critical role in ensuring safe, accurate, and uninterrupted operations.

Our range of oil-free screw compressors, oil-lubricated piston compressors, and rotary scroll compressors delivers reliable air supply while meeting industry requirements such as Class 0 air purity, corrosion resistance, and 24/7 operational capability.

These are the Compressors Used in Chemical Field

A concise overview of the key compressor types that power critical healthcare systems.

01

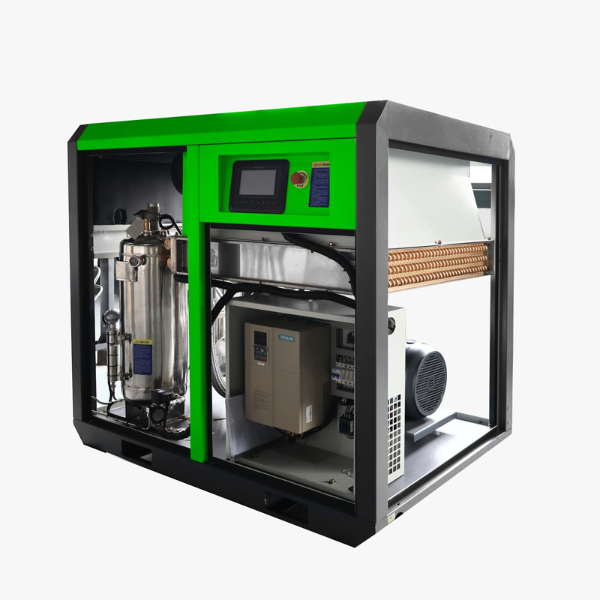

Oil-Free Screw Air Compressor

Instrument air, valve actuation, process control systems

02

Oil-Lubricated Piston Air Compressor

Cleaning, pneumatic tools, utility air

03

ATEX-Certified Explosion-Proof Compressor

Hazardous or flammable zones in chemical plants

04

Portable Diesel or Electric Compressors

Outdoor maintenance, emergency backup, mobile operations

Which type of air compressor is best suited for chemical plants?

For most chemical industry needs, oil-free screw compressors are ideal due to their ability to deliver Class 0 oil-free air, which prevents contamination and ensures safe, consistent operation in sensitive applications like reactor control and pneumatic valves.

Is an explosion-proof compressor necessary in chemical manufacturing?

Yes, in hazardous or flammable zones, ATEX-certified explosion-proof compressors are crucial to ensure safety. PRS offers such models that meet international safety standards for operations involving volatile chemicals or gases.

Can oil-lubricated compressors be used in chemical industries?

They can be used in non-critical zones, but only with proper filtration and separation units to ensure oil does not enter the process line. They're often used for general utility air, cleaning, and maintenance operations.

How does PRS ensure air quality and durability in chemical environments?

PRS compressors are built with corrosion-resistant components, advanced filters, and moisture control systems to ensure clean, dry air output that withstands harsh chemical atmospheres, enhancing both performance and compressor life.

Usage in Chemical field

Reliable air systems built for demanding chemical environments

LETS TALK

Ready for Personalized Support?

Get expert help tailored to your exact needs—whenever you need it.