Air Compressor for Plastic Manufacturing

In plastic manufacturing, compressed air is a critical utility that powers various operations, from injection molding and extrusion to material conveying and cooling systems. PRS Compressors offers high-performance screw and piston air compressors designed to handle the continuous, high-demand air requirements of plastic production lines.

Whether you’re producing PET bottles, molded containers, or plastic parts, our compressors ensure uninterrupted airflow, energy efficiency, and low maintenance. PRS oil-free compressors deliver clean, contamination-free air ideal for sensitive plastic applications, while our oil-lubricated models are engineered for robust industrial use.

Our compressors ensure consistent air supply for injection molding and extrusion, reducing defects and improving production speed.

These are the Compressors Used in Plastic Manufacturing

A concise overview of the key compressor types that power critical systems.

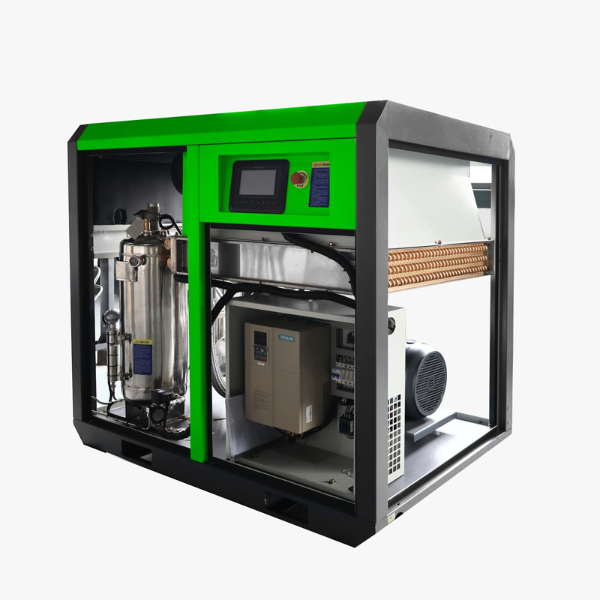

Oil-Free Screw Air Compressor

Oil-Lubricated High-Pressure Piston Compressor

Piston (Reciprocating) Air Compressor

High-Pressure Booster Compressor

Which type of air compressor is ideal for PET bottle manufacturing?

Can I use an oil-lubricated compressor for injection molding?

Is air quality important in plastic production?

How do I choose between piston and screw compressors for plastic production?

Ready for Personalized Support?

Get expert help tailored to your exact needs—whenever you need it.