Medical Air Compressors

PRS Medical Air Compressors provide clean, dry, and oil-free air, meeting the strictest standards for healthcare environments. Designed for hospitals, dental clinics, laboratories, and diagnostic centers, these oil-free medical air compressors ensure consistent airflow with zero contamination, protecting both patients and sensitive equipment.

Engineered for precision, reliability, and silent operation, PRS units feature advanced filtration systems, making them ideal for critical care, surgical applications, and 24/7 healthcare operations. Built for durability and energy efficiency, our medical-grade compressors are trusted by healthcare facilities worldwide.

Working Power: 0.75 kW to 15 kW | 1 HP to 20 HP

Working Pressure: 4 to 8 bar | 58 to 116 psi

Capacity: 5 to 100 CFM | 0.14 to 2.8 m³/min

Benefits of PRS Medical Air Compressors

High-quality, oil-free medical air compressors providing pure, reliable, and quiet air for hospitals, clinics, and healthcare applications.

Longer Lifespan

PRS oil-lubricated compressors ensure longevity by reducing friction and wear on internal parts .

Consistent Performance

Delivers a reliable and steady air supply critical for uninterrupted industrial operations.

Enhanced Cooling

The integrated oil system improves heat dissipation, preventing overheating and ensuring .

Cleaner Air Output

Advanced filtration systems remove oil and contaminants, providing cleaner compressed air.

Why Choose PRS Speed Screw Compressors?

PRS Variable Speed Medical Air Compressors deliver reliable, energy-efficient, contamination-free air for hospitals and clinics.

Dryer Oil Free Screw Air Compressors

Integrated with an inbuilt dryer, PRS Oil Free Screw Compressors ensure moisture-free, ultra-clean air for sensitive industrial applications.

Water Lubricated Oil Free Screw Air Compressors

PRS Water-Lubricated Oil Free Screw Compressors ensure pure, oil-free air using water as a natural sealant—eco-friendly, efficient, and ideal for sensitive industries.

Oil Free Scroll Compressors

PRS Oil Free Scroll Compressors offer ultra-clean, silent, and efficient air solutions ideal for precision industries like medical, dental, and electronics.

Oil Free Piston Compressors

Delivers clean, oil-free compressed air with efficient, low-maintenance performance for sensitive applications.

Products By Industry

PRS medical air compressors deliver clean, oil-free, reliable air for hospitals, labs, and pharma applications.”

Product Details

PRS Medical Air Compressors – oil-free, reliable, and clean air for hospitals, clinics, and pharma applications.”

Oil Separator Tank

Separates oil from compressed air and recycles it for efficient operation.

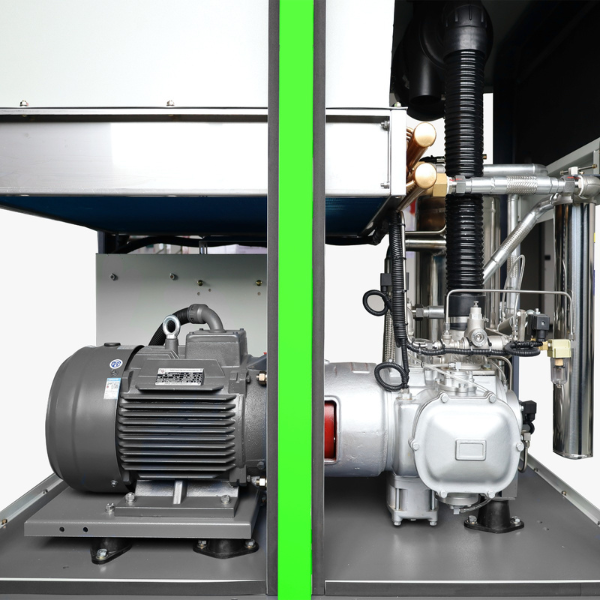

Inverter (VFD)

Controls motor speed and reduces electricity consumption based on load.

Control Panel (PLC)

Monitors compressor operation, displays fault info, and controls functionality.

Air End / Screw Element

The core area where air is compressed using twin screw rotors.

Air Intake Valve

Automatically allows air inside the system when the motor starts/stops.

Air Filter

Ensures clean air by filtering dust and contaminants before compression.

Cooler

Cools down compressed air and oil to avoid overheating and improve safety.

Fan (Cooling Fan)

Supports the cooler by expelling heat and maintaining proper temperature.

Main Motor

Electric motor that drives the compressor, selected based on capacity needs.

Our Products

PRS Medical Air Compressors – high-performance, oil-free solutions for hospitals and clinics, ensuring clean and reliable air for critical medical use.”

Power Up Your Industry with PRS Compressors

Ready to optimize your industrial operations with reliable and energy-efficient PRS Compressors?